Product categories

News center

- Changzhou Wanhao Image Surveyor

- Measuring method for measuring a

- Complete list of maintenance fau

- Wanhao projector operation video

- Wanhao image measuring instrumen

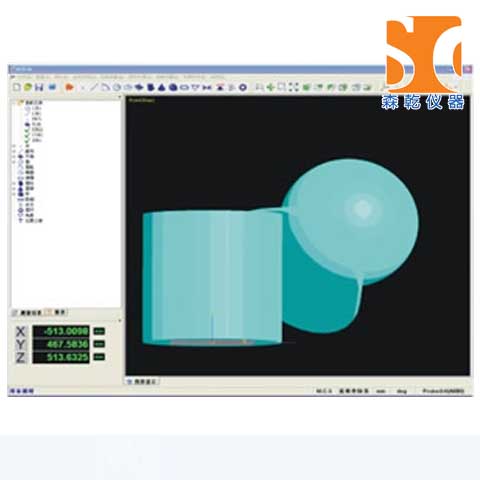

- Operation Manual of Wanhao Image

- Wanhao projector instructions

- Official telephone number of Wan

- Official website of Wanhao Proje

- The processing method of jump nu

- Application of Wanhao image meas

- Domestic exhibitions in 2022 (as

- Explore the current situation of

- A brief analysis of the structur

- What is the function of the tool

- Precautions for use of measuring

Contact us

- Add: Jiangsu province Wuxi City New WU District

- Tel: 0510-81819749

- Fax: 0510-81819749-9

- Email: gc1718@163.com

Product show

Features:

1.Calibrate, save, delete, call the detection system of probe with various shapes by Standard Sphere, Standard Guage and Standard Block.

2.The software can build Datum Coordinate System (DCS) and multiple Part Coordinate Systems (PCS) with various methods to switch between different coordinate systems; transfer among Cartesian coordinate system, cylindrical coordinate system and spherical coordinate system expediently; calibrate, save, delete and call each coordinate system.

3.Able to directly measure all 14 kinds of geometrical elements: point, line, plane, circle, arc, ellipse, key slot, cylinder, cone, sphere, distance, angle, point cloud, ring. It can automatically measure (the system judge which kind of feature automatically after sampling) 8 kinds of basic elements (point, line, plane, circle, arc, cylinder, cone, sphere).

4.When measures various kinds of basic geometrical elements, this software will automatically select probe sphere to obtain the best compensation (excluding point, which the user must assign the compensation direction), improving the measuring accuracy.

5.14 construction methods (including extraction, zooming in / out, translation, combination, parallel, vertical, projection, mirror, symmetry, intersection, rotary, tangency, segmentation, statistics) to construct geometrical elements for measuring elements and pre-installed elements.

6.Able to measure various form and location tolerances of workpiece.

7.Graphic processing for advanced basic geometrical elements, including zoom in/out, translation, window display, full screen display, front view, top view, left view, etc - Makes the result more visually.

8.The report of measuring result and construction result is rich in content and form, such as text report, graph-text report, graph overflow / difference value report, etc. The report can be opened or saved as .gcf format, display shuttle report that indicates specifications of measuring elements.

9.Various kinds of M3D report files can be output into Word or Excel formats, which are good for secondary analysis.

10.Built-in system error correction: available in coordinate positioning compensation, which is available in linear compensation or section compensation, and verticality compensation.

11.Coordinate indication and measuring result are available in conversion between metric units and Imperial units, conversion among degree, minute and second, conversion of centesimal system, and conversion of arc.

12.Available in Simplified Chinese version, Traditional Chinese version or English version, each of them easy to master and operate.

1.Calibrate, save, delete, call the detection system of probe with various shapes by Standard Sphere, Standard Guage and Standard Block.

2.The software can build Datum Coordinate System (DCS) and multiple Part Coordinate Systems (PCS) with various methods to switch between different coordinate systems; transfer among Cartesian coordinate system, cylindrical coordinate system and spherical coordinate system expediently; calibrate, save, delete and call each coordinate system.

3.Able to directly measure all 14 kinds of geometrical elements: point, line, plane, circle, arc, ellipse, key slot, cylinder, cone, sphere, distance, angle, point cloud, ring. It can automatically measure (the system judge which kind of feature automatically after sampling) 8 kinds of basic elements (point, line, plane, circle, arc, cylinder, cone, sphere).

4.When measures various kinds of basic geometrical elements, this software will automatically select probe sphere to obtain the best compensation (excluding point, which the user must assign the compensation direction), improving the measuring accuracy.

5.14 construction methods (including extraction, zooming in / out, translation, combination, parallel, vertical, projection, mirror, symmetry, intersection, rotary, tangency, segmentation, statistics) to construct geometrical elements for measuring elements and pre-installed elements.

6.Able to measure various form and location tolerances of workpiece.

7.Graphic processing for advanced basic geometrical elements, including zoom in/out, translation, window display, full screen display, front view, top view, left view, etc - Makes the result more visually.

8.The report of measuring result and construction result is rich in content and form, such as text report, graph-text report, graph overflow / difference value report, etc. The report can be opened or saved as .gcf format, display shuttle report that indicates specifications of measuring elements.

9.Various kinds of M3D report files can be output into Word or Excel formats, which are good for secondary analysis.

10.Built-in system error correction: available in coordinate positioning compensation, which is available in linear compensation or section compensation, and verticality compensation.

11.Coordinate indication and measuring result are available in conversion between metric units and Imperial units, conversion among degree, minute and second, conversion of centesimal system, and conversion of arc.

12.Available in Simplified Chinese version, Traditional Chinese version or English version, each of them easy to master and operate.